The feed water plays a vital role in the laundry process, directly affecting the quality of washing and the durability of clothing. Understanding the importance of feed water, Thai Tuan LMS has invested in a feed water treatment system for its laundry facility. Let’s explore the feed water treatment system at Thai Tuan LMS below!

Role of the Feed Water System in Industrial Laundry

In the laundry process, the feed water acts as a solvent that helps to separate and dissolve stains from fabrics, specifically:

- Removes dirt and bacteria.

- Enhances laundry effectiveness: softened water allows detergents to dissolve better, saving soap. Furthermore, water that has passed through the treatment system has a neutral pH level, which helps protect fabrics and prevents color fading.

- Protects laundry equipment and prevents damage: safeguards machines from clogging and corrosion, extending their lifespan.

The feed water system ensures a water source free from impurities or harmful chemicals, helping protect users' health and maintain the laundry quality of clothing and fabrics, enhancing washing effectiveness.

Feed Water Treatment Process at Thai Tuan LMS

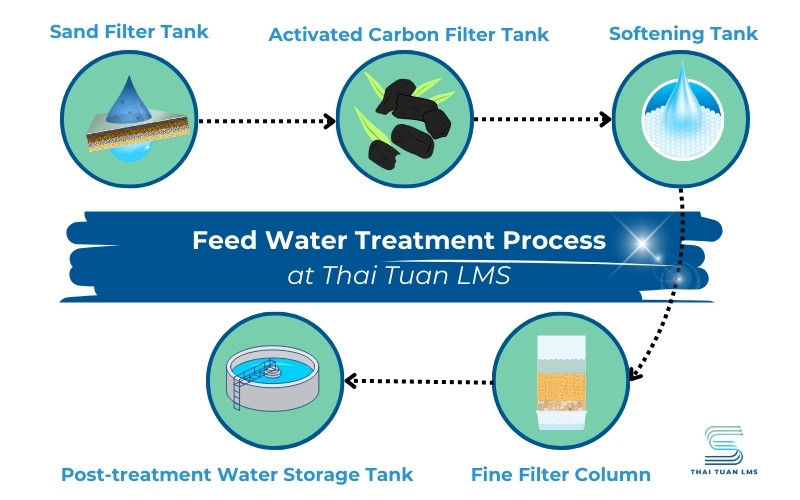

Thai Tuan LMS has invested in a modern feed water treatment system with four filtration stages: Sand Filter Tank - Activated Carbon Filter Tank - Softening Tank - Fine Filter Column, ensuring that the incoming municipal water supply is optimally treated before being used for laundry.

The incoming water source, with a capacity of 40m³/h, is directed into a centralized storage tank to hold water before being pumped through the subsequent filter tanks. Water is gradually pumped through each filter tank to remove sediment and suspended solid particles. At this stage, the water supply is divided into 2 parallel treatment units, equipped with flow meters to monitor the flow rate. Each unit has a processing capacity of 20m³/h.

Sand Filter Tank

The sand filter tank functions to filter out dirt particles in the water. It is a closed filtration system, where the filtration process occurs due to water pressure above the filter media layer. The commonly used filter media includes quartz sand and gravel. As water passes through the filter media, dirt particles are retained on the surface of the filter media, resulting in clear water.

Activated Carbon Filter Tank

After passing through the sand filter tank, the water is directed to the activated carbon filter tank to ensure that the output parameters meet the required standards.

The primary filter media is activated carbon, positioned above layers of support gravel and coarse sand. The water filtration process in the activated carbon filter tank occurs as follows:

Through the porous holes on the surface of the activated carbon, which have a large surface area and strong physical adsorption capability, the flow of water allows impurities, bacteria, and organic pollutants to be captured, making the water purer.

Additionally, the activated carbon filter tank also removes dissolved chemicals and toxic substances from the water, effectively deodorizing and decolorizing it. Water that passes through the activated carbon filter will continue to the softening tank to reduce water hardness.

Softening Tank

The softening tank operates based on the principle of ion exchange using resin beads. Water is softened by using cation resin beads (positively charged ions). As water flows through the cation resin column (containing ions with a positive charge), heavy metal ions in the water are separated through ion exchange with strongly alkaline metals. These beads absorb Ca2+ and Mg2+ ions in the water.

These ions are responsible for forming scale deposits on plumbing systems and fixtures, affecting the lifespan of the equipment.

Fine Filter Column

Water from the softening tank is then directed to the fine filter column to remove larger particles and impurities that are suspended and greater than 5 µm in size.

After a working cycle, it is necessary to restore the processing capability of the filter columns. When the pressure drop increases by 2 kgf/cm2 (approximately 28 psi), the membrane will become fouled, reducing its filtering capability, and requiring a backwash to clean the accumulated dirt on the membrane.

Post-treatment Water Storage Tank

Water after being treated from the fine filter column from the two units will be directed to the post-treatment water storage tank for storage and pumped for boiler supply to serve the laundry process.

The feed water, after being treated by the feed water treatment system at Thai Tuan LMS, meets the standards for feed water to production, thus maximizing the effectiveness of laundry chemicals used.

Thai Tuan LMS - Perfect Laundry Service with Advanced Technology

At Thai Tuan LMS, we pay attention to every step in the laundry process. With the largest laundry factory in Southeast Asia, a total investment of 56 million USD, modern equipment imported from Germany, and a highly skilled workforce… Thai Tuan LMS confidently commits to the quality of our services:

- Clean laundry, disinfected, optimizing the life cycle of fabric fibers

- Use of internationally standard laundry chemicals that are safe and user-friendly

- Timely delivery to the right location

- Accurate quantity and the correct type of fabric delivered

- 24/7 customer care

To experience laundry services at Thai Tuan LMS, please contact our hotline: 0901.661.166 for free consultation support.

Vietnamese

Vietnamese  English

English