Thai Tuan LMS is always at the forefront of applying advanced and environmentally friendly technologies. At Thai Tuan LMS, the wastewater treatment system is designed and constructed according to standard procedures, ensuring effective treatment of wastewater generated during the laundering process, thus contributing to the protection of water sources and the living environment in line with sustainable development.

Wastewater Treatment Process at Thai Tuan LMS

The wastewater treatment process at Thai Tuan LMS is carried out in the following sequence:

Collection Pit -> Cooling Tower -> Equalization Tank -> Rapid Reaction Device -> Dissolved Air Flotation Tank (DAF) -> MBBR Tank -> Aerobic Biological Tank -> Settling Tank -> Disinfection Tank -> Sludge Storage Tank -> Sludge Press.

Collection Pit

Wastewater generated from the factory's production process is first free of coarse waste and then flows through the drainage system into the collection pit.

At the collection pit, wastewater undergoes preliminary treatment with a coarse screening device with an opening size of 5 - 8mm, after which the wastewater is pumped to the cooling tower.

Cooling Tower

Wastewater from the laundering process has a high temperature of 70 - 80°C. At the cooling tower, the heat from the water is extracted and released into the atmosphere through a cooling system consisting of fans and cooling plates. After that, the wastewater flows into the equalization tank.

Equalization Tank

The equalization tank serves to regulate flow and stabilize the concentration of pollutants in the wastewater before it moves to downstream units. The equalization tank is aerated by an air blower and distributed via a perforated pipe system to mix the wastewater, preventing sedimentation, anaerobic decomposition, and foul odor generation. The treated wastewater is then pumped to the rapid reaction device.

Rapid Reaction Device

The rapid reaction device is designed in a zigzag tube shape to enhance the mixing of chemicals into the wastewater. The chemicals introduced are PAC coagulant and Anionic Polymer coagulant which are successively added into the initial segments of the rapid reaction device as part of the process:

- PAC chemicals are used to break down the stability of colloidal particles and help them bond together to form small flocs.

- Anionic Polymer chemicals assist in coagulation, enlarging the size of the sludge flocs, which can then be removed in the DAF tank.

Dissolved Air Flotation (DAF) Tank

The DAF tank is a breakthrough compared to conventional flotation methods in the wastewater treatment system at Thai Tuan LMS. Microfine air bubbles are created by a compressor and introduced into a pressurized tank along with the recirculating wastewater before being sent into the shallow flotation apparatus, rather than being directly supplied as in conventional flotation devices.

%20Tank.jpg)

The main components of the DAF tank consist of five key parts: the tank body, water distribution mechanism, dissolved air distribution system, framework mechanism, and water extraction mechanism.

The inflow and outflow pipes, as well as the sludge collection pipe, are concentrated in the central area of the tank body, with the water distribution system, water extraction system, and dissolved air release components connected to the tank framework and surrounding the tank's center. Oils and suspended solids are separated from the DAF tank and directed to the sludge storage tank. The remaining wastewater continues to flow to the Moving Bed Biofilm Reactor (MBBR) tank.

Moving Bed Biofilm Reactor (MBBR) Tank

The MBBR tank is a biological treatment tank that utilizes a biofilm formed on suspended media. This medium is relatively thin with a large surface area, allowing microorganisms to form and develop within protected slots while still maintaining regular contact with the wastewater. The biofilm that adheres to the media is responsible for thoroughly treating organic compounds in the wastewater. These media can take the form of circular discs.

The biofilms formed on the surface of the media consist of three different layers. The innermost layer is an anaerobic biofilm, the middle layer is a microaerobic biofilm, and the outermost layer is an aerobic biofilm. This stratification of different microbial layers significantly enhances the MBBR's capability to treat nitrogen, phosphorus, and BOD compared to traditional activated sludge tanks.

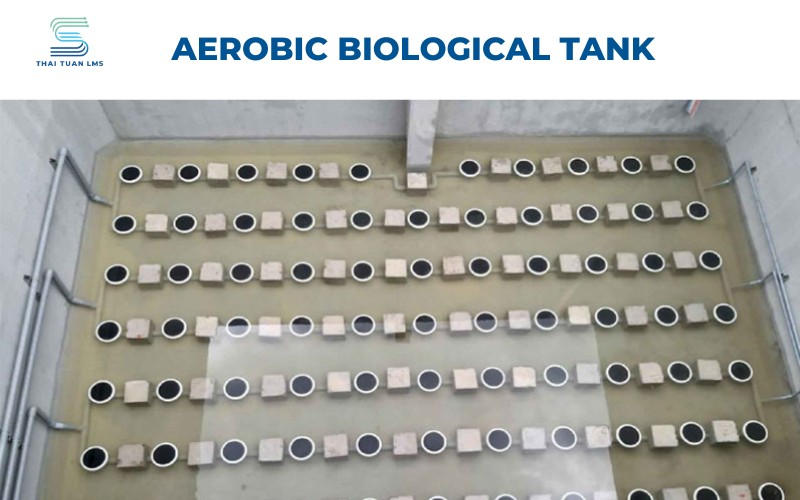

Aerobic Biological Tank (Aerotank)

In the aerobic biological tank, organic substances in the wastewater are treated.

Wastewater flowing from the MBBR tank will naturally flow into the aerobic biological tank. Here, the organic compounds in the wastewater are treated. A hot air blower provides additional air to supply oxygen for aerobic microorganisms to thrive. Under continuous blower operation, the population of aerobic microorganisms decomposes the organic compounds in the wastewater into inorganic compounds like CO2 and H2O. Furthermore, in this aerobic environment, bacteria will absorb phosphorus and nitrogen beyond normal levels, facilitating cell synthesis, maintenance, energy transportation, and the excess storage of energy in the cells for later stages.

The microorganisms in this aerobic biological tank help decompose organic materials in the wastewater and absorb energy to transform them into new cells. Only a portion of the organic matter is completely oxidized to CO2, H2O, NO3–, SO₄²-, etc.

The microorganisms present in the activated sludge system include Pseudomonas, Zoogloea, Achromobacter, Flavobacterium, Nocardia, Bdellovibrio, Mycobacterium, and two types of nitrifying bacteria, Nitrosomonas and Nitrobacter. Additionally, various filamentous bacteria such as Sphaerotilus, Beggiatoa, Thiothrix, and Geotrichum are present, along with Nitrosomonas and Nitrobacter.

Settling Tank

Water from the aerobic biological tank flows through a distribution section to the settling tank. The settling tank's function is to separate the activated sludge that has been treated in the aerobic biological tank. The clarified wastewater flows into the disinfection tank.

The settled sludge is recirculated back to the MBBR tank and then to the aerobic biological tank to maintain the appropriate amount of sludge, while the excess sludge is directed to the sludge storage tank.

Disinfection Tank

In the disinfection tank, Javen chemicals are added to kill pathogens such as E. coli, Coliforms, etc., to meet the wastewater discharge standards of Phuc Long Industrial Park.

Sludge Storage Tank

The sludge storage tank contains excess sludge from the settling tank, as well as sediment and oil from the DAF tank. Here, the water separates from the sludge and returns to the collection pond to continue the treatment process in the wastewater treatment system.

Sludge Press

The sludge press used in the wastewater treatment system at Thai Tuan LMS is a conveyor belt sludge press. This device is employed to facilitate the mechanical and biological dehydration of sludge, with advantages including the production of dry sludge, high solid retention rates, moderate energy requirements, and relatively low operational and investment costs.

At the sludge dewatering machine, Cation Polymer chemicals are pumped in to aid in binding the sludge together. The dewatered sludge will be stored in a sludge storage area and transported for treatment according to regulations.

At Thai Tuan LMS, wastewater is treated through a standard treatment system that meets B QCVN standards, with a wastewater treatment capacity of up to 1400m³ per day/night. We ensure that the quality of the wastewater released into the environment meets the standards, as we are committed to protecting the living environment, which is also our development orientation.

Thai Tuan LMS - The Perfect Laundry Solution, High-Tech Technology

Thai Tuan LMS proudly provides industrial laundry services focused on leading the green environmental protection movement in Vietnam. With a complete investment in modern machinery and equipment imported entirely from Germany, as well as a qualified intake water treatment system and an effluent wastewater treatment system, we confidently commit to service quality.

- One-way laundry process, ensuring clean fabrics, optimizing fabric lifespan, and preventing cross-contamination.

- Using Diversey chemicals that are safe and environmentally friendly.

- Fast delivery - on time - in the right quantity - with the right quality.

- Standard wastewater treatment system.

- 24/7 customer service.

To experience industrial laundry services or integrated laundry management services, please contact our hotline at 0901.661.166 for free consultation and support.

Vietnamese

Vietnamese  English

English