The laundry process is one of the factors that assess the quality of laundry services and the credibility of the laundry unit. At Thai Tuan LMS, the laundry process is a one-way system that not only enhances washing efficiency but also prevents cross-contamination. Below are the detailed steps of the high-tech laundry process currently applied at Thai Tuan LMS.

High-Tech Laundry Process at Thai Tuan LMS

To avoid cross-contamination of linens, the washing process at Thai Tuan LMS operates as a one-way system, ensuring that the path of linens moves in one direction—from the dirty area to the clean area.

Diagram of the high-tech laundry process at Thai Tuan LMS:

1. Collection of dirty items and transportation to the factory

Dedicated vehicles for transporting dirty laundry at Thai Tuan LMS will collect and conduct a preliminary sorting of dirty laundry at the laundry unit. After this, items are transported back to the factory.

During the collection of dirty items, it is important to note:

- Adherence to safety regulations when lifting heavy items

- Dirty items must be placed in designated bags

- Do not drag or pull items on the floor; use suitable carts for transporting dirty items

- Ensure that clean items are isolated from dirty items to prevent contamination

- Observe traffic laws while transporting

2. Dirty Linens Sorting

After the transportation vehicle delivers the dirty laundry, it will be taken to the dirty laundry area of the factory for sorting. This step is crucial as it affects the choice of washing program, washing chemicals, temperature, washing time, and mechanical action used in the laundry process to achieve optimal washing effectiveness.

At Thai Tuan LMS, dirty linens sorting is based on the following criteria:

- Sort by item type: towels, sheets, bathrobes, pillowcases, etc.

- Sort by fabric type: each fabric has a suitable washing temperature; this step requires sorting by fabric type: linen, cotton, silk, etc.

Example:

Wool or silk items are only suitable for washing at low temperatures with neutral pH.

Cotton items can be washed at high temperatures but are susceptible to chemical effects if not handled carefully.

- Sort by the level of dirtiness and type of stain: different dirt levels require different handling methods. Common stains include inorganic and organic substances.

Inorganic stains include rust, pen marks, synthetic colors, paint, etc.

Organic stains include blood, mud, food stains, etc.

- Sort by color: white items are always washed separately to avoid color transfer.

- Sort by size of fabric items.

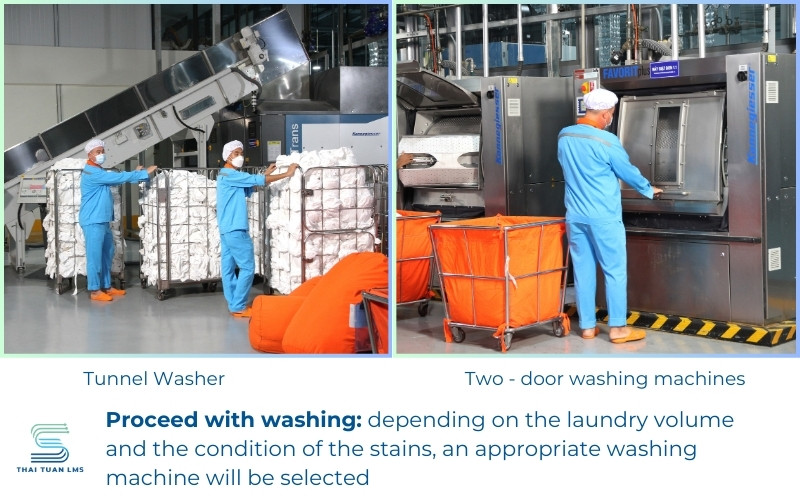

3. Washing

Based on the classified dirty fabric items, either tunnel washing machines or two-door washing machines and suitable washing programs will be selected to achieve the highest efficiency.

- Tunnel washing machines: used when there is a large volume of laundry, light stains, and fabrics without decorative materials.

- Two-door washing machines: used when the amount of laundry is small, lighter or smaller items, or heavily soiled items that have been pre-treated.

At Thai Tuan LMS, the machinery and equipment system is fully imported from Kannegiesser, Germany, including 4 tunnel washing machines and 8 two-door washing machines, with a washing capacity of up to 150 tons per day/night, ensuring all laundry needs of customers are met. To experience laundry services or receive advice about laundry services at Thai Tuan LMS, please contact our Hotline: at 0901.661.166 for free consultation.

The main factors affecting washing efficiency have been researched by the R&D team at Thai Tuan to develop specific washing programs for different types of stains and fabrics.

- Temperature

- Chemicals

- Washing time

- Mechanical action

- Human factors

The combination of modern equipment and expertise ensures the best washing results.

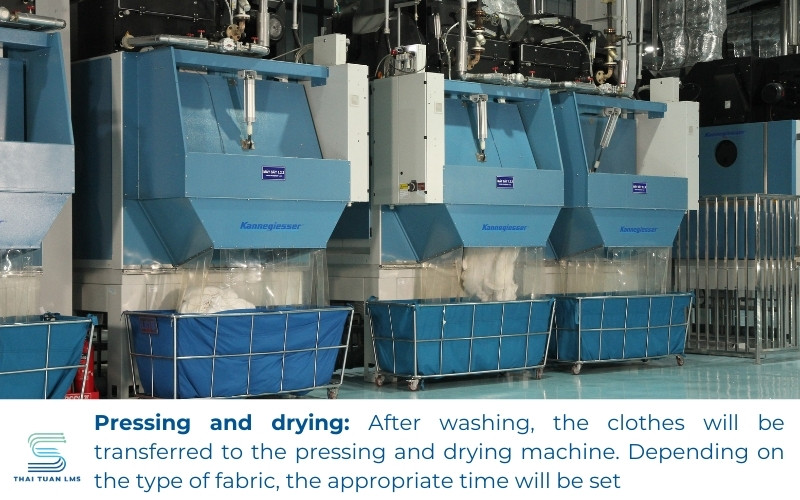

4. Pressing and Drying

After washing, the items will be transferred to the pressing and drying machines. Depending on the type of linen, the pressing and drying program will be set with appropriate time settings to ensure that the linen does not become overly dry shrink, or get burned.

5. Quality Inspection

In this step, the QC team will check the quality of the linens based on the following criteria:

- Appearance of the finished fabric: whether it is torn or has color bleeding, and if the stains have been cleaned.

- Indicators: moisture content, brightness, pH level.

Note: If customers need to check for mold, microorganisms, or bacteria, these assessments must be conducted by a third-party unit and will incur additional costs.

Linens that pass the quality check will be sent for ironing and folded according to high-tech laundry procedures. Linens with defects will be sent to the repair area for adjustments. Linens still containing stains will be treated accordingly based on the extent of the staining.

6. Ironing

Linens that meet the quality requirements will be moved to the ironing area. This process uses high-temperature steam, which also helps in sterilization.

At Thai Tuan LMS, the ironing system is carried out through a high-tech and automated machinery line, thereby enhancing ironing efficiency and shortening the overall laundry process compared to manual methods.

7. Folding

Depending on the type of linen, the folding method will vary. After ironing and folding, the items will be checked for quantity and packaged manually according to the required specifications.

8. Linen Packaging

Depending on the specific customers, the packaging method will vary. Typically, the basic packaging for linen items is as follows:

- Bed covers and sheets (5 pieces per bundle)

- Bath towels (10 pieces per bundle)

- Bath mats (20 pieces per bundle)

- Hand towels, washcloths, and pillowcases (30 pieces per bundle)

9. Delivery to Customers

Once the high-tech laundry process is completed, and the linens have passed quality checks, a delivery vehicle will pick up the cleaned linens from the clean laundry area and deliver them to the customers, ensuring timely delivery, correct quantities, and quality.

4 Reasons to Choose Thai Tuan LMS as Your Laundry Partner

Thai Tuan LMS, with the largest laundry facility in Southeast Asia, offers unique features that guarantee effective laundry solutions for our clients.

Integration of the LMS Linen Management System

We use intelligent RFID recognition technology to capture, read, and store linen information within our system using radio wave frequency. All information about the fabrics will be stored in the RFID management application, allowing customers to access real-time status updates with just a touch, eliminating the need for physical inventory checks as before.

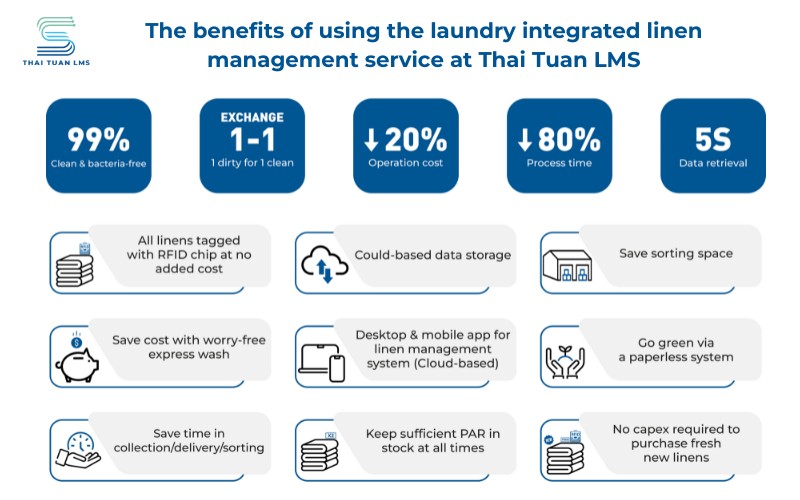

Benefits of using the laundry service integrated with the linen management system unique to Thai Tuan LMS:

- No need to invest in linen inventory while having 4 pars of RFID-tagged linens, with always 2 linen sets at the hotel

- Savings on storage costs

- Savings on personnel costs

- Savings on urgent laundry costs

- 5 seconds to retrieve data, reducing processing time by 80%

Thai Tuan LMS is a pioneer in high-tech laundry services, applying intelligent RFID recognition technology and providing software for easy management on both Android and iOS operating systems. Throughout our partnership with Thai Tuan LMS, your access account will be fully supported free of charge.

Dedicated Delivery and Pickup Vehicles for Timely Service

To prevent cross-contamination of linen, Thai Tuan LMS has invested in 2 separate lines for DELIVERY and PICKUP, including 30 Isuzu trucks and 4 Ford Transit vans.

We commit not only to timely delivery and pickup of fabrics but also to flexible arrangements according to the specific requests of each customer for special delivery times.

ESD Static Electricity Elimination Technology in Clean Rooms

Thai Tuan LMS applies ESD static electricity elimination technology with strict procedures through several stages, ensuring that clothes are free from static cling after washing, which is essential for factories and production workshops. This ensures the safety of workers and prevents damage to machinery.

People Make a Difference

Our personnel is the key factor that allows Thai Tuan LMS to confidently assert its superior service quality. All staff members are well-versed in their working processes and are thoroughly trained.

Moreover, we have dedicated R&D, logistics, QA, and QC teams to ensure the highest laundry efficiency.

Our customer service team is always ready to assist, with a commitment to respond within 24 hours of your inquiry.

With significant capabilities, modern imported machinery from Germany, internationally standard laundry chemicals, highly skilled personnel, a robust logistics system, and stringent quality management procedures, Thai Tuan LMS confidently positions itself as a high-tech laundry service provider, offering the CLEANEST - FASTEST - MOST DURABLE laundry service with DEDICATED CUSTOMER SUPPORT.

Thai Tuan LMS commits to service quality as follows:

- Linens after washing are clean, white, and disinfected, ensuring smoothness, and softness, and maintaining fabric structure without wear, staining, tearing, or deteriorating.

- Prevention of cross-contamination

- Timely delivery to the correct location

- Accurate quantity and type of fabrics delivered

- 24/7 customer support

If you have any questions or wish to experience the laundry services at Thai Tuan LMS, please contact our hotline: 0901.661.166 for free consultation support.

Vietnamese

Vietnamese  English

English